Custom-edged

blades

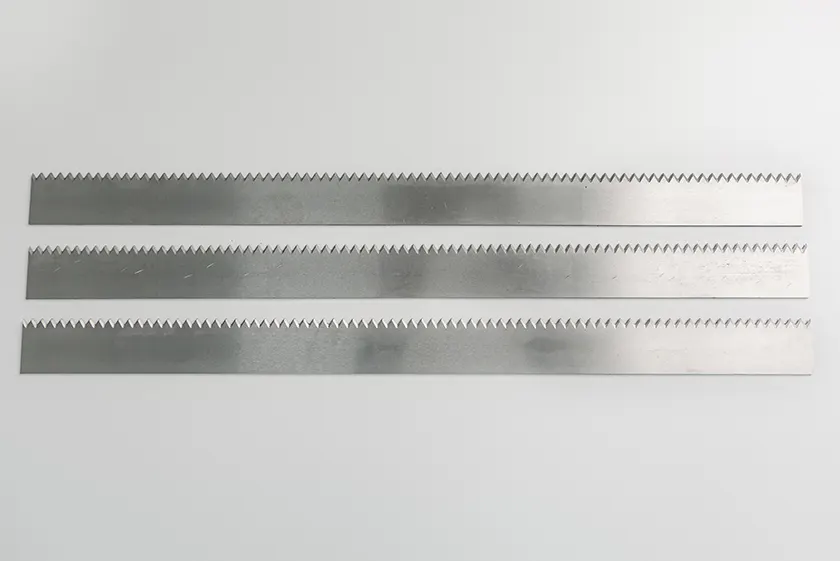

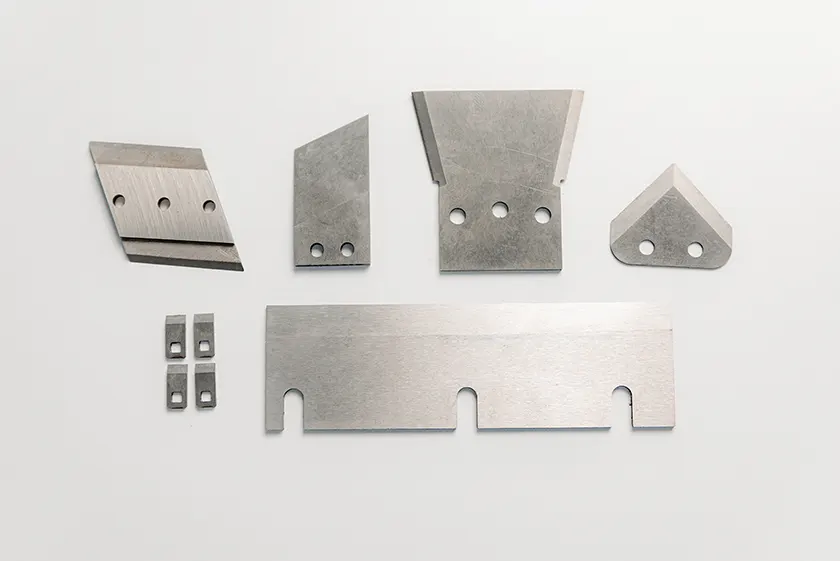

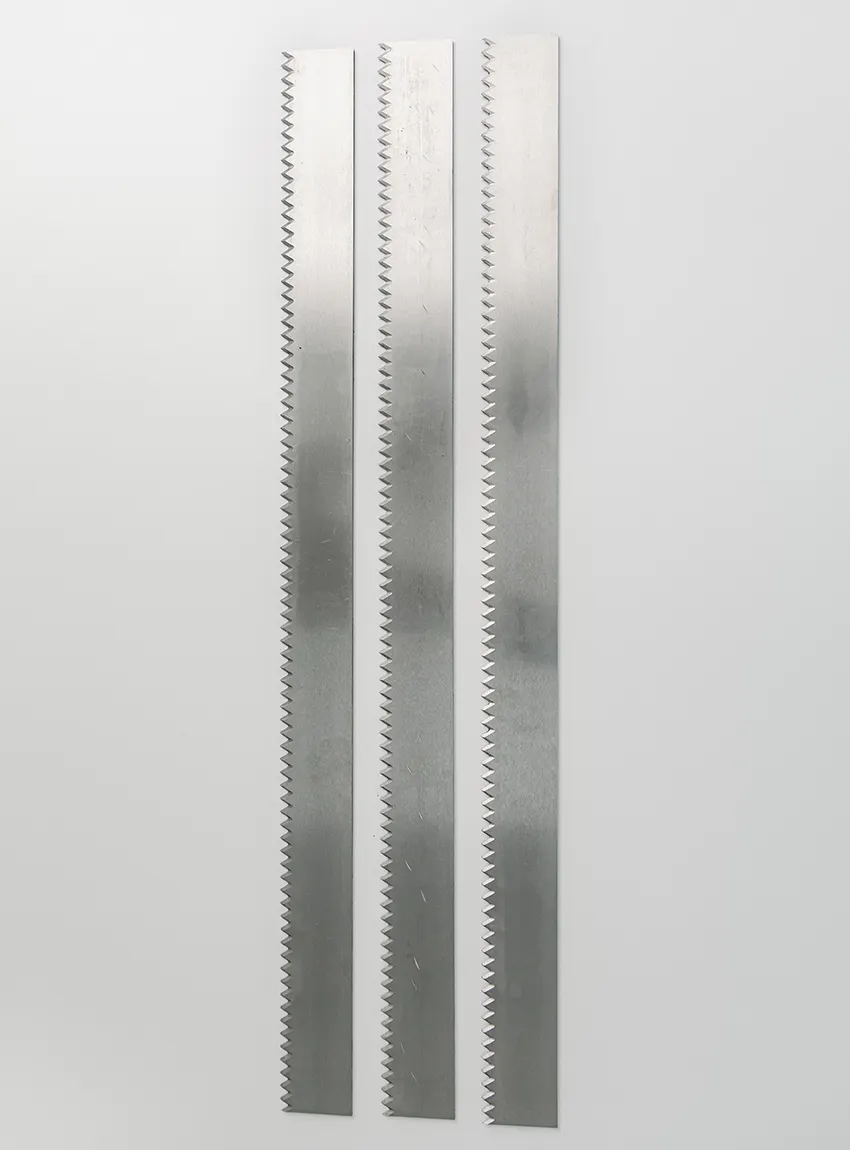

Depending on the cutting geometry and the blade’s edge design, we classify blades as serrated or straight, selecting one or the other based on the material to be cut and the desired cutting characteristics.

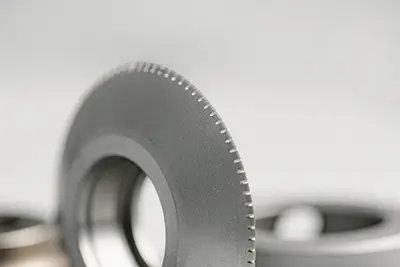

Serrated blades have teeth along the edge, which dig into the material and enable efficient cutting for heavy and tough jobs. They are commonly used for materials such as wood, plastic, or metal.

Serrated blades are manufactured with a wide range of tooth angle steps, and can have pointed, flat or rounded teeth, depending on the cutting application required for that blade.

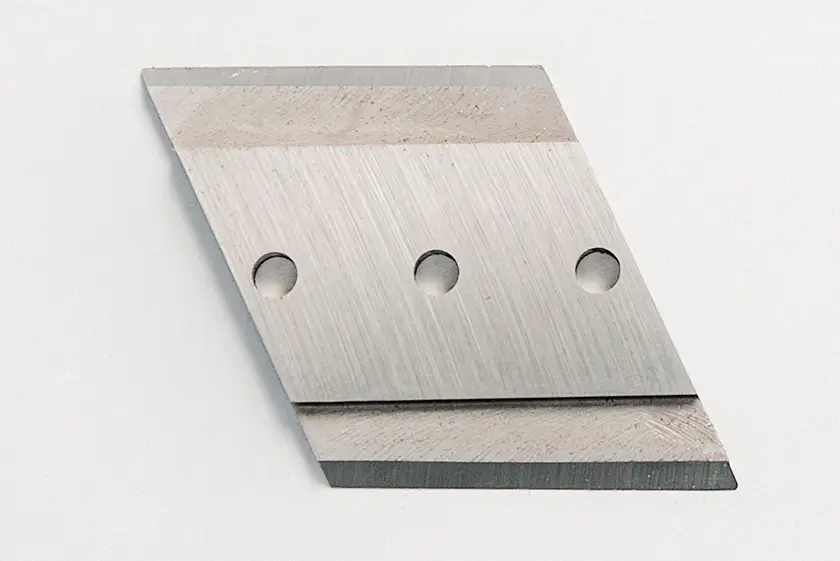

On the other hand, straight blades have no teeth on the edge. They are used for cutting softer materials like paper, cardboard, or fabric. These blades have a smooth, straight surface that slides over the material, delivering a clean, delicates, and precise cut.

It is important to choose the right blade for the job needed to be done. That is why at Cuchillas CIBA, we provide advice on the best option, ensuring that your serrated or straight blade meets your needs.

Experts in serrated and straight blades

If you need serrated blades, straight blades, or any other type of cutting tool, we can supply them because we work with custom blade manufacturers. We are motivated by the most complex challenges.